Do You Need a Fast Turnaround For Gray and Ductile Iron Castings? You have heard it said – Time is Money. Well, if that is the case and if you can get your casting in 7-14 days then you are saving money. Utilizing skilled workers Rapid Prototyping can help jump start your project and bring …

Do You Need Investment Castings?

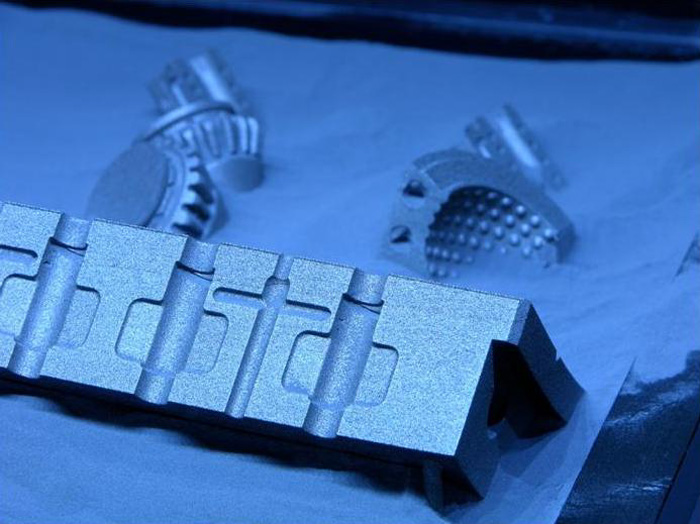

The Investment Casting process goes back many thousands of years. It would be fair to say that modern industry has perfected the process. Many would say – still perfecting. It competes with other casting processes, but why would a casting buyer choose this, or why would an engineer think of this process over another. I …

Transferring Tooling To A New Supplier

If your company has products that require castings sometimes you find yourself ready to make a switch to a new foundry. Depending on the situation – it could be a relationship issue, quality, delivery, or just being told they do not want to do your work anymore. Regardless of the reason, or the situation, sometimes …

Thinking About Gray Iron Applications

One of the key traits of gray iron is its ability to resist wear even when oil supply is limited for lubrication. That is why many designers have looked to this metal when creating engine components, gear blanks, housings, cylinder heads, manifolds, cast iron frying pans, manhole covers machine bases, brake components and many other …

Welcome to The Casting Company, Inc.

Welcome to The Casting Company, Inc., where we help you take your designs from prototype to production. If you have a project with which you need help, give Brian Moore a call at 317-721-7303. We provide our Engineering Group and OEM customers with the best quality work at the best price, at the facility that …