Green Sand Foundry

Prototypes – Production – Machining

With the ability to produce small castings and up to 150lb castings, our foundry has the experience you need to deliver your products on time and at a very high-quality level. Whatever your requirements we are prepared to meet your expectations.

Our foundry will dig in to help you with product engineering questions and with our turn-key value add culture we can help you from beginning to end with your project.

- Low to high volume – complex shapes

- Intricate cores

- Automated Molding System

- Shell Cores

- Hunter 20 with 20×24 Deep Flask – Automatic Molding

- In house Heat Treat and Aging.

- Robert Sinto – FBO II – 16×20 – Automatic Molding

- (1) Osborn Squeezer, up to 15” x 26”

- (4) Osborn Roto-Lift up to 24” x 32” and 32” x 32” and Air Set Molding

- Vibratory Finishing

- Materials Poured – A356, 319, 355, A357, 413, 713 Tenzalloy, 535 Almag, ZA-12

- 19 CNC Mills and Lathes for machining services

- Quicker Turns on Quotes

- Core Processes: Airset, Isocure, Shell

We are committed to the environment and the health and safety of our customers, our staff, and the community where we operate.

We are committed to the environment and the health and safety of our customers, our staff, and the community where we operate.

![]() Tooling

Tooling

Our tooling capabilities include:

- Reconditioning of Transferred Patterns & Core Boxes.

- In-House Machining Fixtures & specialty tooling

- CNC Cut – New Pattern and Core Box tooling

- Rigging of new & existing tooling

![]() Quality

Quality

- CMM Dimensional Layouts with 1st Article

- 3D Scanning for Dimensional Verification

- PPAP’s and Certifications

- ISO 9001:2015 / (PED) Certified, Pressure Equipment Directive

- QA Display with Digital Work Instructions

![]() Engineering Services

Engineering Services

Design Assistance

Design Assistance- Quick Turnaround on Quotations

- Casting Simulation Software

- SOLIDWORKS 3D Design Software

- We partner with multiple tool shops for rapid turnaround on production and prototype tools.

- Tooling can be constructed in-house using wood, urethane, and aluminum.

![]() Industries Served

Industries Served

- Compressors, Blowers, Pumps, Petroleum, HVAC, Machine Tool

- Food Processing & Preparation

- Aftermarket Automotive and various other industries nationwide

- Agricultural

- Construction, Power Generation, Electrical, Power Line, Lighting

- We love the challenge of your industry!

With over 25 years experience, our pattern shop is able to construct patterns in a timely manner to meet the continuing customer demands.

For a quick turn around quote on tooling, please contact us and we will be happy to help in any way possible.

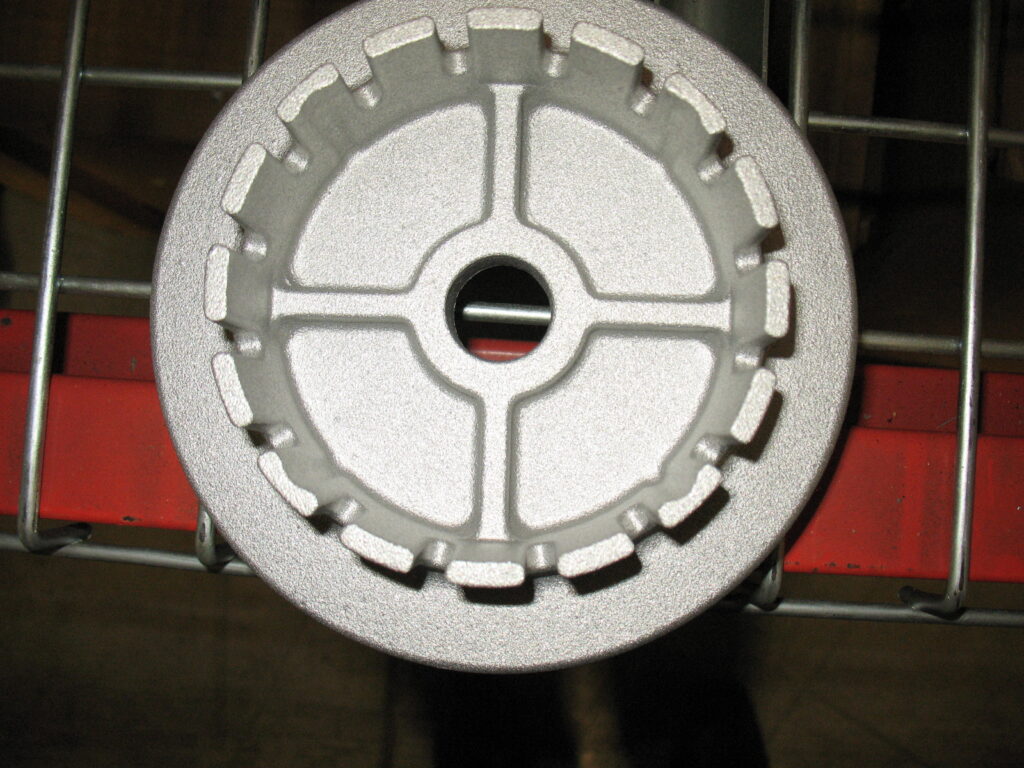

Aluminum Gallery: Click Image to Enlarge

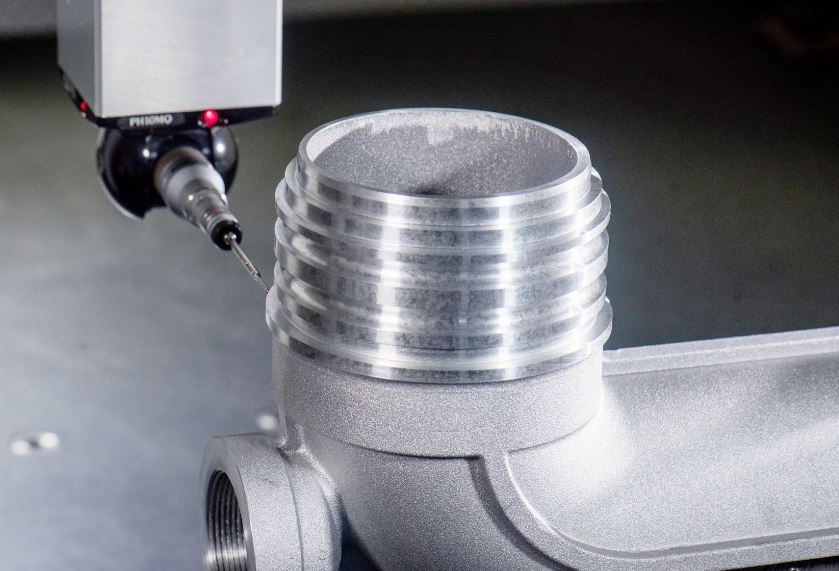

CMM Aluminum Sand Casting Quality Check

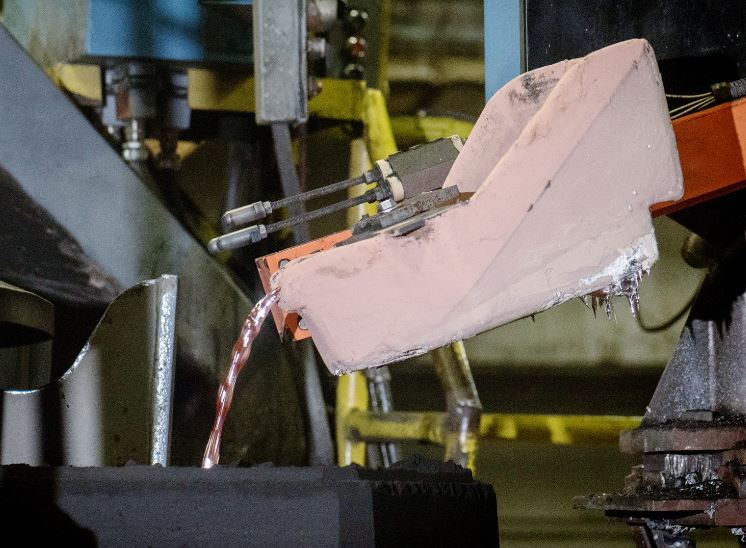

Molten Aluminum Pouring Into Mold

Molten Aluminum Pouring Into Mold

Aluminum Sand Casting Machining

Molten Aluminum Pouring Into A Green Sand Mold

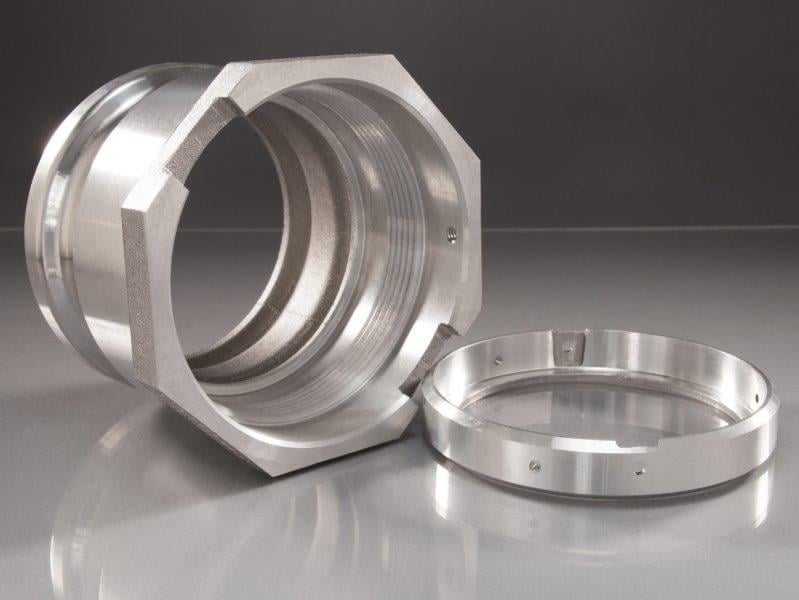

Aluminum Sand Casting Surface Finish

Aluminum Green Sand Mold Cooling In Foundry

Aluminum Sand Casting Base Surface Finish

Aluminum Sand Casting With Machining