No Bake Molding Process

New for 2021 our Foundry replaced all of their green sand equipment with proprietary No-Bake (UMM) Universal Molding Equipment that will run almost any type of tooling.

Combined with our SRS sand reclamation system from Europe, our foundry is one of the first American foundries to utilize this technology.

There is MINIMAL COST to adapt tooling. This will give us 3-4 times increased capacity and allow us to have much shorter lead-times.

Industries Served

Pouring good metal for Heavily Cored Castings for the pump, valve, power transmission, and heavy industry. Whatever your industry – if we can pour your part and it fits the foundry – we will make it

Gray Iron Poured

- Class 20, 30, 35,40

- Special Alloy as needed (Chrome, Moly, Nickel, Copper, etc.)

Ductile Iron Poured

- 100-70-30

- 80-55-06

- 65-45-12

- 60-40-18

Pouring Weights

- 1 lb. to 1200 lb.

- Core competency: 75 lb. to 900 lb. (these weights fit us best)

Melting

- 2 x 3000 lb. Inductotherm Coreless Induction Melters

Flask Sizes – Up to’48 x 60

Many larger flasks for floor molding

Pattern Facilities

- Mounting, Gating, and Minor repairs done in house

- Utilize preferred pattern shops for pattern production and major repairs

Core Processes

- Shell

- No Bake

Cleaning Equipment

- 15GN Pangborn Tumble Blast

- Snag grinder

- Swing grinder

- Hand grinders

Quality Assurance Equipment

- Brinnel Hardness Testing

- Sonic Thickness Testing

- Spectrometer

- Microstructure Analysis

- Tensile Analysis

- Casting and Pattern Layout Facilities

Advantages of the No-Bake Casting Process

- Large, heavy, and very intricate castings produced in a single mold

- Better surface finish – smooth 150 RMS

- Customers can reduce costs by taking large fabrications and making one part

- No-bake molds are very ridged, and the tensile strength allows for thin sections to be cast. This mold strength allows for less draft requirements in the design.

- Not all cases, but inexpensive tooling options since this process is compatible with most pattern materials like wood, plastic, metal, and other materials.

- Minimal tooling wear

- Less prone to gas porosity

- Low to mid-range volume

When designing for No-Bake castings remember that draft is required to pull the part – Sharp corners, or other angles should be minimized. Uniform section thickness should be utilized as much as possible. The No-Bake process does allow for your designers to be a bit more daring with the designs. If we need to test and build the prototype first – we can 3-D sand print the molds and remove the need for tooling on the first run.

For more information or a quote, contact us.

No-Bake Sand Casting Gallery

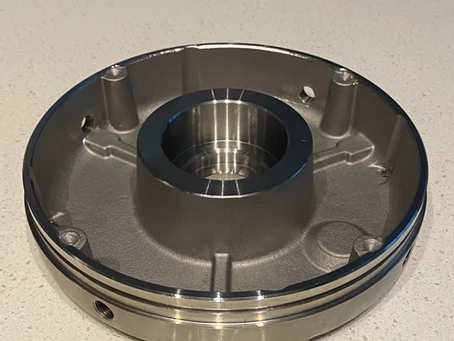

No-Bake Gray/Ductile Iron Castings

No-Bake Gray/Ductile Iron Castings

No-Bake Gray/Ductile Iron Castings

No-Bake Gray/Ductile Iron Castings

No-Bake Tooling for Gray Iron/Ductile Iron

No Bake Molding Equipment

Gray Iron and Ductile Iron Components

Iron Casting

No Bake Molding System for Gray Iron and Ductile Iron