AS-9100 Registered — ITAR Registered

Direct Metal Laser Sintering — Fast Turn-Around

High Quality Parts — One-Off Samples

We offer the latest technology in 3D Additive metal printing. Main cost drivers for DMLS are (1) machine time, (2) post-processing labor, and (3) material.

DMLS Process & Applications

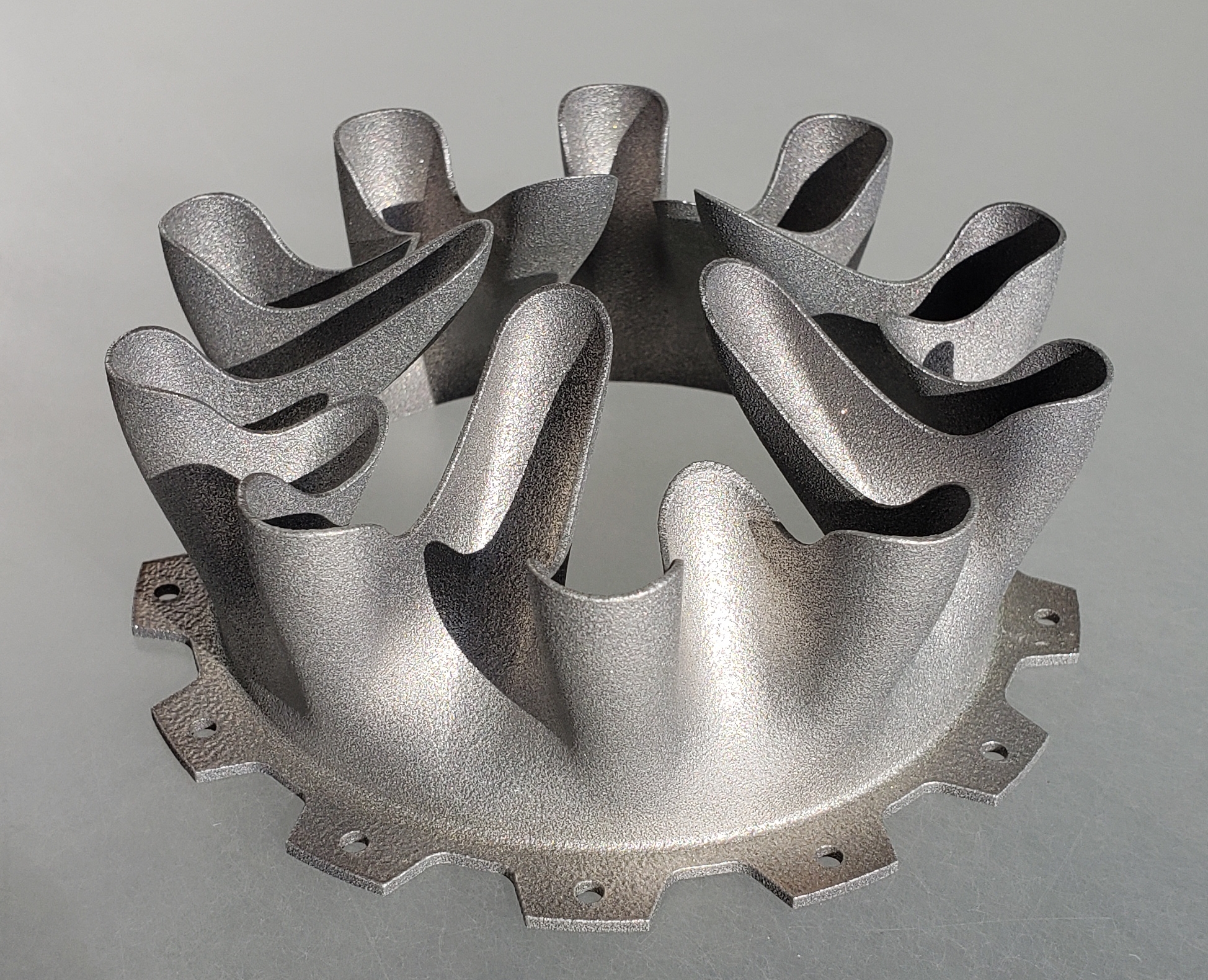

DMLS is an additive metal fabrication technology that creates metal parts with highly complex geometries directly from 3D CAD data, fully automatically, in hours instead of days or weeks, and without any tooling. The DMLS software “slices” into thin layers which the DMLS machine then builds layer by layer, fusing metal powder into a solid part by melting it locally using a focused laser beam.

DMLS technology is used for both:

- Rapid prototyping – decreases development time for new products

- Production manufacturing as a cost saving method – simplifies assemblies and complex geometries

The technology is useful to a variety of manufacturing industries, including:

- Military

- Aerospace

- Dental

- Medical

- Automotive

- Engineering

- Motor racing

- Other industries that have small to medium size, highly complex parts

- Tooling industry to make direct tooling inserts

Benefits of the DMLS Process

DMLS has many benefits over traditional manufacturing techniques, including:

- No special tooling required

- Parts can be built in a matter of hours

- Allows for more rigorous testing of prototypes

- Can use most alloys. Currently available alloys used in the process include:

- AlSi10Mg Aluminum – used for cast parts with thin walls and complex geometry

- CobaltChrome 404 – excellent mechanical properties (strength, hardness etc.), corrosion resistance and temperature resistance

- MaragingSteel M300 – excellent strength combined with high toughness, easily machinable, excellent polish ability

- NickelAlloy IN718 – good tensile, fatigue, creep and rupture strength at temperatures up to 700°C; outstanding corrosion resistance

- StainlessSteel 316L – good mechanical properties, especially excellent ductility in laser processed state; widely used in a variety of engineering applications

- StainlessSteel 15-5 and 17-4 – excellent mechanical properties, especially in the precipitation hardened state; widely used in a variety of medical, aerospace and other engineering applications requiring high hardness and strength

- Titanium Ti6 AL4V – excellent mechanical properties, corrosion resistance, low specific weight and biocompatibility

Titanium Components

- Prototypes can be functional hardware made out of the same material as production components

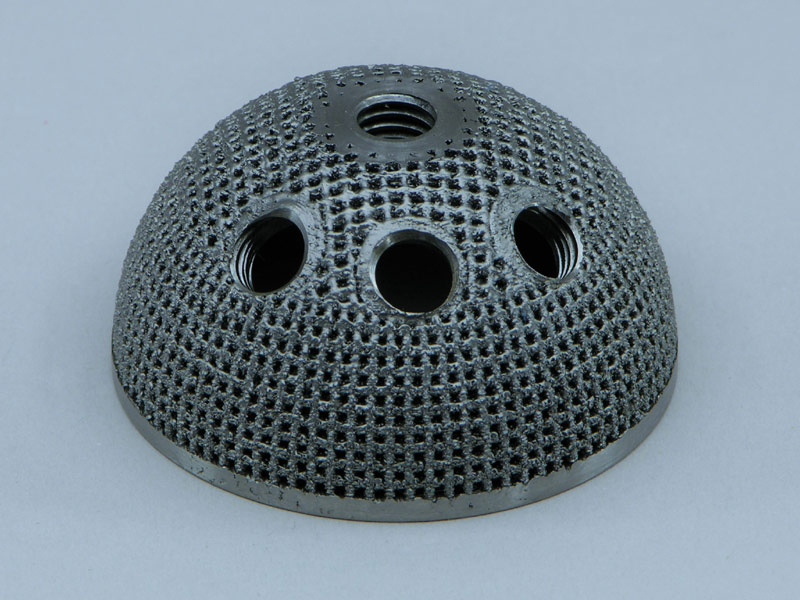

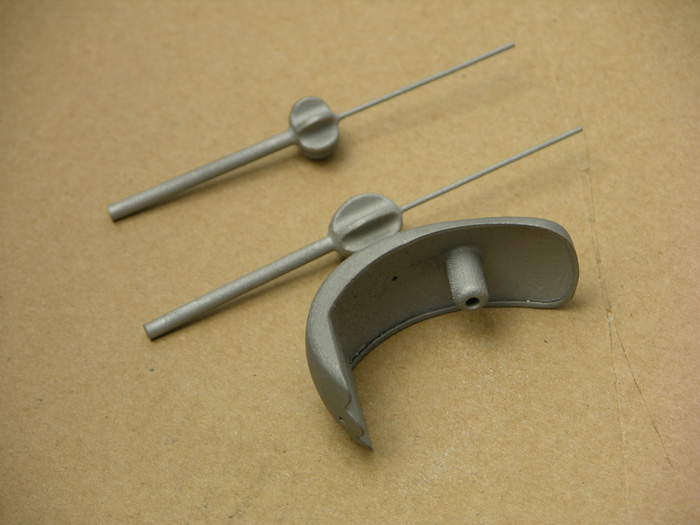

- Create internal features and passages that can’t be cast or otherwise machined

- Complex geometries and assemblies with multiple components can be simplified to fewer parts

- Cost effective assembly

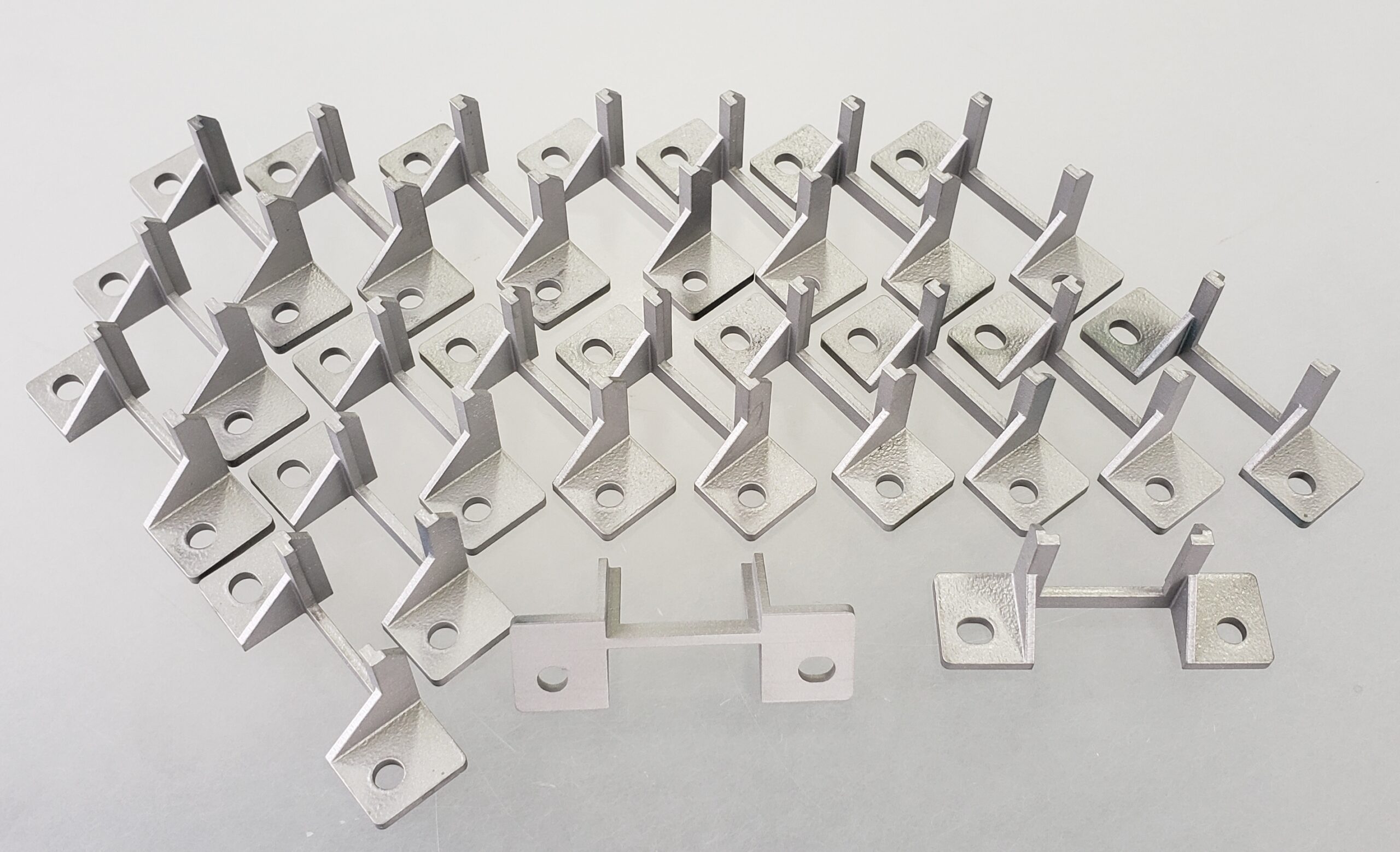

- Convenient for short production runs

- Ideal for both prototype & small production runs.

- Builds complete in hours or days.

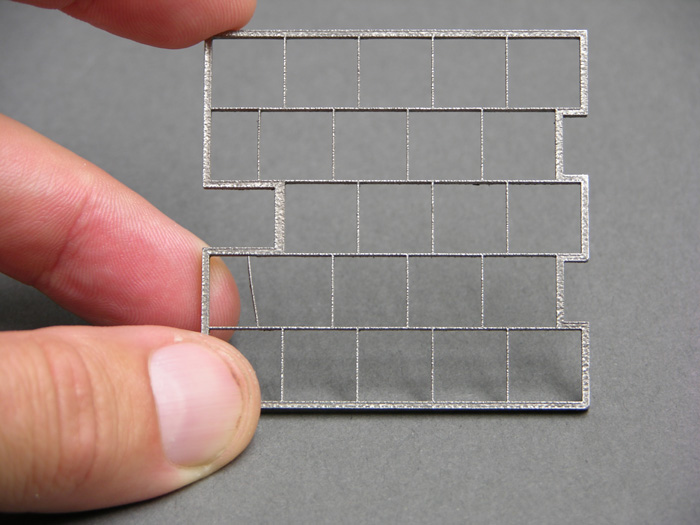

- We build our components in layers of 20-70 microns.

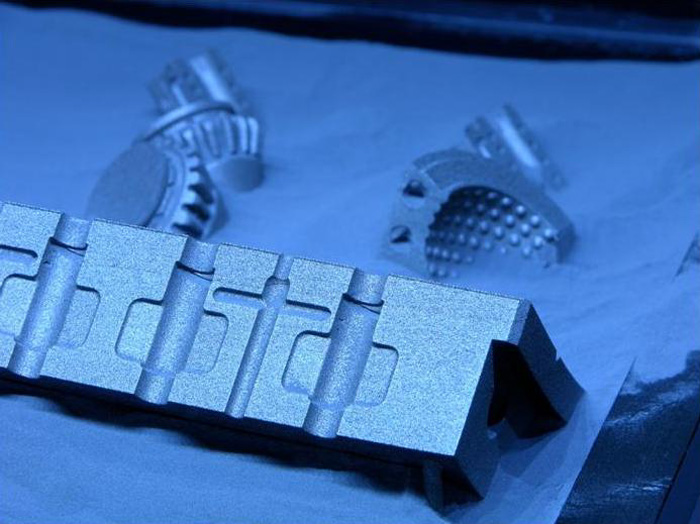

- Completely dense functional parts with complex geometries.

- Excellent detail resolution and surface quality with high hardness and strength.

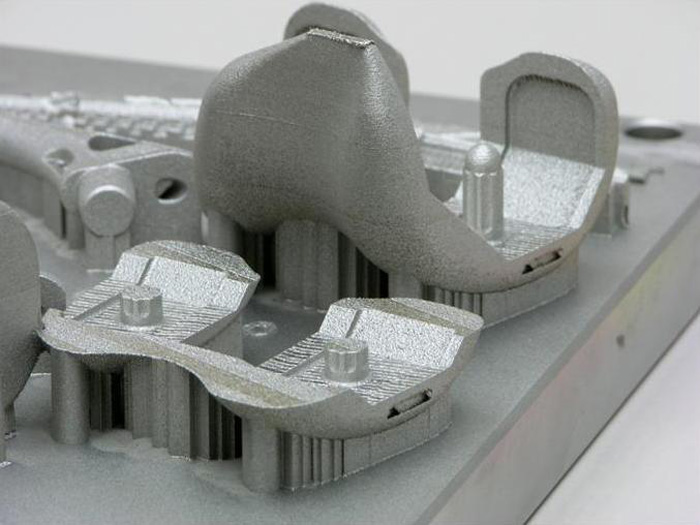

- We build inserts for tool makers – Conformal Cooling – we can create almost infinite routing options for Cooling Channels that cannot be reached via conventional methods like machining, or EDM. Constant temperatures can improve the part.

- Designers can have more freedom and choose complex shapes.

DMLS Gallery

Post Processing Options

- Abrasive Blast

- Shot Peen

- Electro Polish

- Electro Plate

- Extrude Hone

- Optical Polish

- CNC Finishing

- EDM

- Welding

- Micro Machining Process (MMP)

This technology delivers unlimited potential for engineers to create previously impossible solutions, embracing a new era of design-driven manufacturing.

Equipment

- 3 – Renishaw AM400 (Single: 400 W Laser – Direct Metal Laser Melting) Additive Mfg. machines

- 1 – Renishaw AM500Q (Qty 4:500 W Lasers– Direct Metal Laser Melting) Additive Mfg. machine

- 2 – 3DP Plastic Printers .7m x .7m x .7m

- 1 – Cyber Gage 360 3D scanner .002um

- 3 – Makerbot FDM Plastic Printers

- 2 – Forms Lab SLA Plastic Resin Printer

- 1 – Hurco VM20i 20”x40” VMC 40 taper

- 1 – Toyoda 3 axis 27”x45” VMC 40 taper

- 1 – Fanuc RoboCut α-C600iB Wire EDM

- 1 – Mazak 5 axis MC’s 500mm 40 taper

- 1 – Clausing 3VS08CNC Knee Mill

- 2 – CMM’s

- Manual Tool Room Equipment

DMLS-Produced Parts

Please contact us for a quick turn around quote on DMLS Prototypes; we will be happy to help in any way possible. Send us your project in a Step file. They are very useful 3D files that are very precision and customizable.

The Casting Company, Inc. strives to consistently exceed the expectations of our customers. We value the opportunity to demonstrate how our capabilities can give your company a competitive edge in the market.