Our Services

Since 1990, we’ve been delivering solutions for industrial markets. We pay special attention to your needs, pride ourselves on delivering consistent, outstanding results, and adhere to strict ethical and legal guidelines. Browse our service areas to learn more about how we can help you.

Why The Casting Company Inc.

The Casting Company will take your project from prototype to completion based on our extensive knowledge of every aspect of manufacturing success. Our customers know we provide top-quality manufactured products produced with the most efficient and cost-effective methods available.

30 Years of Experience

We’ve helped hundreds of OEMs reach their production goals using our decades of industry experience representing premier manufacturers in the USA.

Production Need Responsiveness

We work directly with all of our engineers to provide the best possible balance of design quality, cost, and production time.

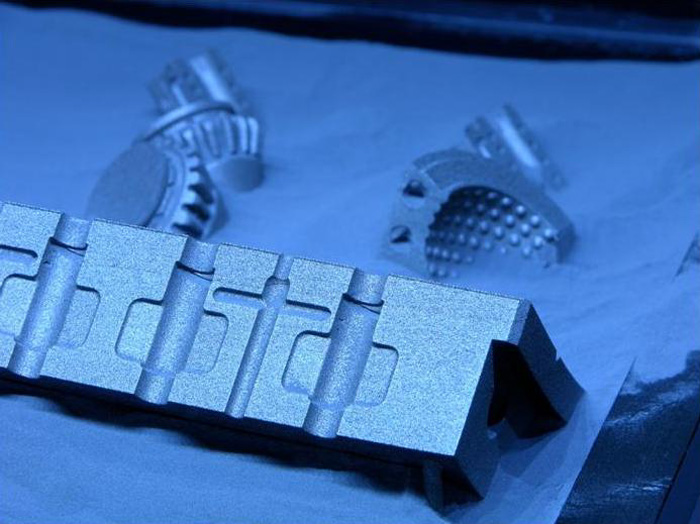

DMLS | 3-D Metal Printing

We take your design and create complete complex parts that cannot be produced by traditional methods such as casting, forging, and machining.

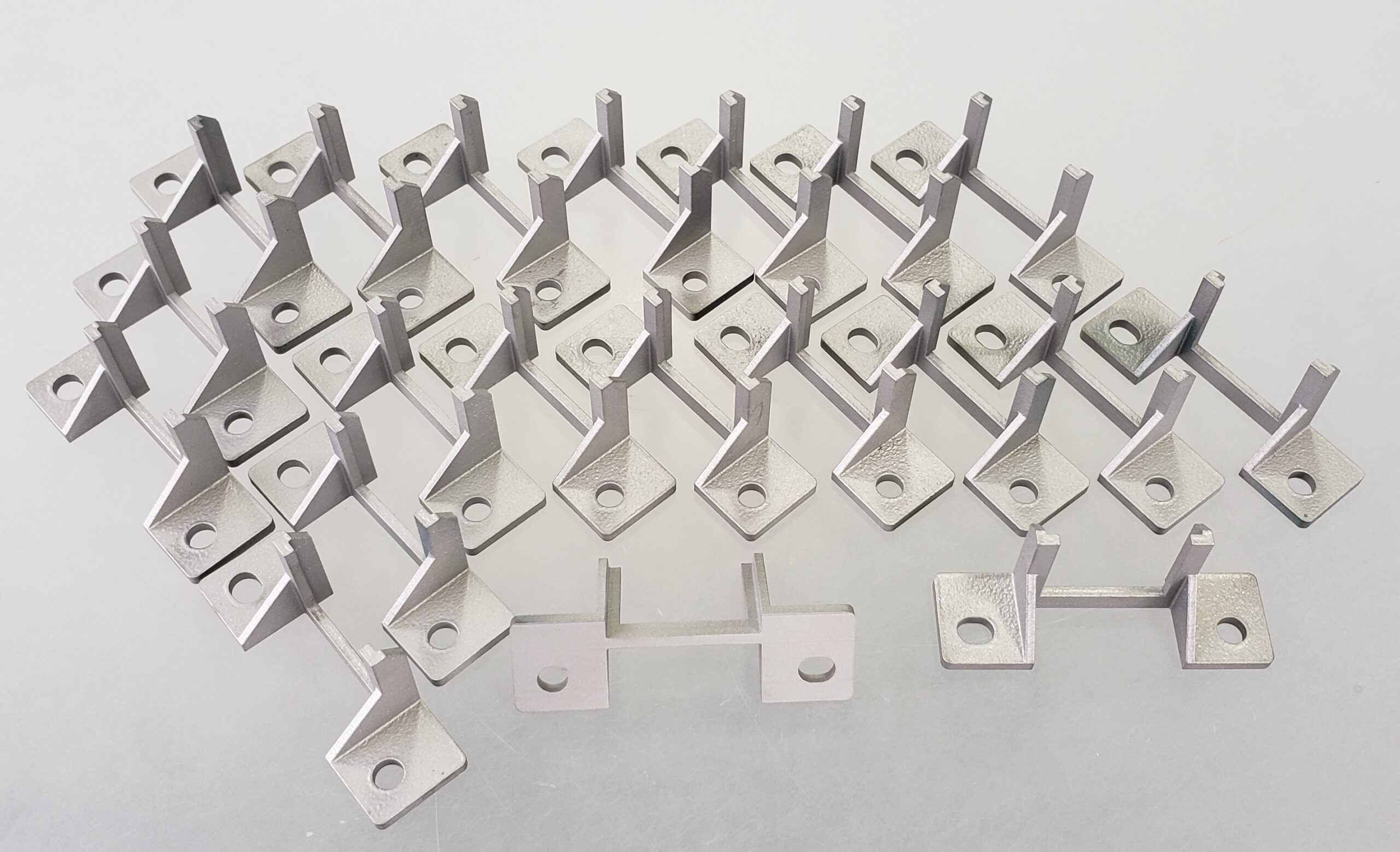

Castings To Meet Every Industrial Need

The Casting Company can meet your metal casting needs with the highest quality castings available today.

Metal Castings, Metal Injection Molding, Tight Tolerance Parts, Customized Metal Alloys, Complex Shape, Close Tolerance, Eliminate Secondary Operations

Gray and Ductile Iron No Bake Sand Castings

No Bake Molding Process New for 2021 our Foundry replaced all of their green sand equipment with proprietary No-Bake (UMM) Universal Molding Equipment that will run almost any type of tooling. Combined with our SRS sand reclamation system from Europe, our foundry is one of the first American foundries to utilize this technology. COMPATIBILITY: If your current …

Aluminum Sand Molding Capability

Green Sand Foundry Prototypes – Production – Machining With the ability to produce small castings and up to 150lb castings, our foundry has the experience you need to deliver your products on time and at a very high-quality level. Whatever your requirements we are prepared to meet your expectations. Our foundry will dig in to …

Investment Casting

Investment Castings – High Quality – Low Cost – Metal Components Get Your Prototypes (NO TOOLING REQUIRED) In As Little As 7 – 15 days We stand behind our products. If you aren’t happy, we aren’t happy. Having the best customer service available is the very core of our company. We Deliver Eliminate all tooling …

Shell Molded Steel

Our Shell Mold foundry pours many grades of carbon and stainless steels. This process is well suited for medium to higher volume production, but we can also do the lower volumes as well. The shell mold process offers tolerances as close as +/- .030 per inch with excellent dimensional repeatability ensuring consistency from one order …

Protected: PRIVATE: Gray and Ductile Iron No Bake Sand Castings

There is no excerpt because this is a protected post.

Protected: PRIVATE: Gray and Ductile Iron No Bake Sand CastingsRead More

Metal Injection Molding

Stainless Steel, Molybdenum, Tool Steels, Tunsgten, ASTM F15 Kovar, ASTM F75 CoCr, Stainless, Copper Alloy Steels The Casting Company provides expert resources for all of your precision metal injection molding (MIM) needs. We specialize in projects that require complex custom injection metal moldings. With the MIM process there is virtually no design restrictions or compromising. …

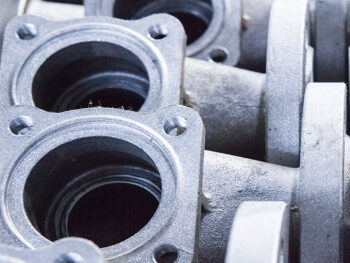

Gray & Ductile Iron Casting

Proud to Make Gray Iron in the USA Our engineering is CAD capability in Auto CAD — Solid Works — Solidification Modeling — Pattern Engineering. We have capacity and can respond to your needs! Low – Medium – High Volumes Our Foundry is a Privately Owned (ESOP) 200,000 square feet 350 employees Pour gray & …

Zinc Die Casting

Very efficient, Very flexible and a full-service competitive manufacturing partner – At Your Service! Looking to reduce your costs? Maybe Zinc is the Answer! Advantages of Zinc Die Castings vs. Other Processes Design engineers turn to zinc die castings for component parts because the manufacturing process combines precision and cost effectiveness with the exceptional mechanical …

Die Casting

Die casting is a unique process in which we force molten metal under high pressure into a mold cavity. The mold us usually from two hardened steel dies that have been machined into the desired shape. It is very similar to plastic injection molding process. Most die castings are made from non-ferrous metals like copper, …

Success Stories

“I want to take this opportunity to thank you for the great work your company has provided for our project scope. Your delivery has met our expectations and I appreciate your dedication to customer service. I look forward to working with you again in the future.”

Harley-Davidson

Our customer wanted a robust part that could simulate material that might be used in production. The material chosen was PH1. It is similar to a 15-5 stainless steel.

Major Tier 1 Automotive Supplier

Read Case Study

We utilized the Direct Metal Laser Sintering (DMLS) process to meet the very tight deadline and make this project a success.

Manufacturer of Suppression Technologies

Read Case Study

We created new tooling that allowed our customer to improve their overall assembly process while reducing costs.

Manufacturer of Hand Tools

Read Case Study

Looking for immediate answers to your questions?

Schedule a phone or Zoom call today!

Take Your Designs from Prototype to Production — TALK WITH US ABOUT YOUR PROJECT